Kt Kingtronics GKT- Aluminum electrolytic capacitor is our leading product, we produce and sell best Radial Type, Snap-in Type and SMD chip type Aluminum electrolytic capacitor.

Compared with other capacitors, Aluminum electrolytic capacitor is small in size,large in capacity and highly resistant. Its applications ranging from computers and navigation systems requiring high performance and high reliability to AV (Audio & Visual) equipment, camera flashes, etc.

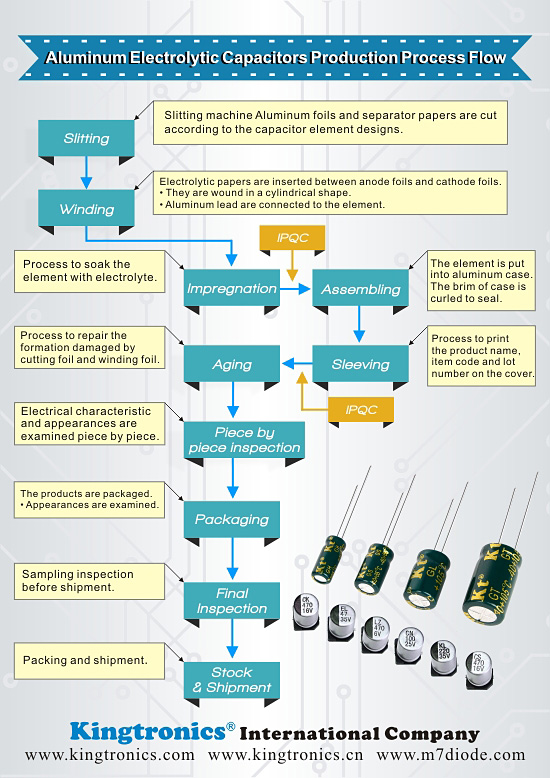

Kt Kingtronics shares you the production process of Aluminum Electrolytic Capacitors. Details please see the below table.

| 1 | Slitting | Slitting machine Aluminum foils and separator papers are cut according to the capacitor element designs. |

| 2 | Winding | Electrolytic papers are inserted between anode foils and cathode foils. They are wound in a cylindrical shape. Aluminum lead are connected to the element. |

| 3 | Impregnation | Process to soak the element with electrolyte. |

| 4 | Assembling | The element is put into aluminum case. The brim of case is curled to seal. |

| 5 | Sleeving | Process to print the product name, item code and lot number on the cover. |

| 6 | Aging | Process to repair the formation damaged by cutting foil and winding foil. |

| 7 | Piece by piece inspection | Electrical characteristic and appearances are examined piece by piece. |

| 8 | Packaging | The products are packaged. Appearances are examined. |

| 9 | Final Inspection | Sampling inspection before shipment |

| 10 | Stock and Shipment | Packing and shipment |

Leave a Comment